(1)構成

影像測量儀是一種由高解析度CCD彩色鏡頭、連續變倍物鏡、彩色顯示器、視頻十字線顯示器、精密光柵尺、多功能數據處理器、數據測量軟件與高精密工作臺結構組成的高精度光學影像測量儀器。

加工定制:否

分辨率:0.001 (mm)

測量行程:250*150*200 ( mm)

品牌:英斯特力

型號:VME-4030

放大倍率:光學0.7-4.5X

影像28-180X

操作方式:手動

測量精度:(3+L/200)um

外形尺寸(長*寬*高):1000*650*1650 (mm)

JVB250的規格參數:

①測量范圍:X坐標:250mmY坐標:150mm

調焦行程:7坐標:200mm

x、Y、坐標分辨率:0.0005mm

③儀器準確度:(3+L/200) um其中L為被測長度,單位mmCCD攝像機:1/3”彩色攝像機,象素數:795(H)×596(V)

⑤物鏡放大率:0.7~4.5×連續變倍,影像放大28~~180倍。與放大率對應的物鏡工作距離:75mm~90mn

⑦與放大率對應的物面最大高度:150mm~~130mm工作臺承重:30kg

金屬工作臺尺:450mm×300mm

⑩主機外形尺寸:580mm× 750mm×660mm

(2)工作原理

影像測量儀是基于機器視覺的自動邊緣提取、自動理匹、自動對焦、測量合成、影像合成等人工智能技術,具有點哪走哪自動測量、CNC走位自動測量、自動學習批量測量的功能,影像地圖目標指引,全視場鷹眼放大等優異的功能。同時,基于機器視覺與微米精確控制下的自動對焦過程,可以滿足清晰影像下輔助測量需要,亦可加入觸點測頭完成坐標測量。支持空間坐標旋轉的優異軟件性能,可在工件隨意放置或使用夾具的情況下進行批量測量與SPC結果分類。

被測工件置于工作臺上,在投射或反射光照明下,工件影像被攝像頭攝取并傳送到計算機,此時可使用軟件的影像、測量等功能,配合對工作臺的坐標采集,對工件進行點、線、面全方位測量。

影像測量儀是利用表面光或輪廓光照明后,經變焦距物鏡通過攝像鏡頭,攝取影像再通過S端子傳送到電腦屏幕上,然后以十字線發生器在顯示器上產生的視頻十字線為基準對被測物進行瞄準測量。并通過工作臺帶動光學尺,在X、Y方向上移動由DC-3000多功能數據處理器進行數據處理,通過軟件進行演算完成測量工作。影像測量主要是利用變焦距物鏡將物體放大,再將其投影到屏幕上進行的工具。

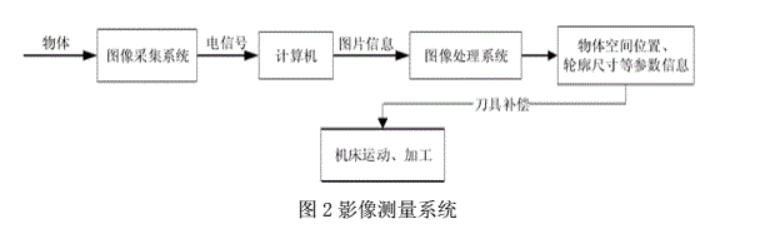

影像測量,即通過CCD攝取外界物體圖像,通過光電轉換,將圖像數據信息傳送給計算機,通過計算機上的圖像處理軟件進行圖像處理、幾何計算,最后得出物體位置信息、輪廓尺寸參數等物體信息,再利用后續的專用反饋控制系統對機床加工進行反饋控制,具有非接觸性、實時性以及高精度性等特點。影像測量系統的大體框架如圖所示:

圖像采集系統包括光學成像系統(照明光源)、圖像傳感器、光學鏡頭以及圖像采集卡,系統采集的圖像質量直接影響到后續處理過程的準確性,是高精度測量的重要前提,圖像處理算法的優劣也直接影響系統的實時性和精度。

英斯特力儀器是一家集研發、生產及銷售于一體的 影像測量儀,拉力試驗機, 硬度計 ,探傷儀, 粗糙度儀, 測厚儀, 金相設備廠家, 致力于為客戶提供更好的檢測儀器。

(1)

Image measuring instrument is a kind of high precision optical image measuring instrument composed of high resolution CCD color lens, continuous zoom objective lens, color display, video crosshair display, precision grating ruler, multi-function data processor, data measuring software and high precision table structure.

Processing and customization: no

Resolution :0.001 (mm)

Measuring stroke :250*150*200 (mm)

Brand: Inst Force

Model: the VME - 4030

Magnification: optical 0.7-4.5x

Images of 28-180 - x

Operation mode: manual

Measurement accuracy :(3+L/200)um

Dimensions (L * W * H):1000*650*1650 (mm)

JVB250 specification parameters:

① Measuring range :X coordinate :250mmY coordinate :150mm

Focusing stroke :7 Coordinates :200mm

X, Y, coordinate resolution :0.0005mm

③ Instrument accuracy :(3+L/200) um where L is the measured length, unit mmCCD camera :1/3 "color camera, pixel number :795(H)×596(V)

⑤ Magnification of the objective lens :0.7~4.5× continuous multiplication, image magnification 28~ 180 times. The working distance of the objective lens corresponding to the magnification :75mm ~ 90Mn

⑦ And magnification corresponding to the maximum height of the surface :150mm~ 130mm workbench bearing :30kg

Metal table size :450mm x 300mm

⑩ Host dimensions :580mm× 750mm×660mm

(2) Working principle

Image measuring instrument is automatic edge detection based on machine vision, automatic horse, af, measuring synthesis, synthetic images, such as artificial intelligence technology, with which automatic measurement points which take walk, CNC automatic measurement, automatic learning batch measuring function, image map goal guidance, the whole field of excellent functions such as eagle eye amplification. At the same time, the automatic focusing process based on machine vision and micron precise control can meet the need of auxiliary measurement under clear image, and can also be added to the contact probe to complete coordinate measurement. Excellent software performance to support spatial coordinate rotation, batch measurement and SPC result classification in the case of workpiece placement or use of fixture.

The measured workpiece is placed on the workbench, under the projection or reflected light lighting, the workpiece image is captured by the camera and transmitted to the computer. At this time, the software image, measurement and other functions can be used to cooperate with the coordinate acquisition of the workbench to measure the workpiece point, line and plane in all directions.

Image measuring instrument is to use surface light or contour illumination, the longitude variable focal length objective lens through the camera lens, image and then transmitted to the computer screen through the S terminal, and then to the crosshair generator generated on the display of the video crosshair as the benchmark for the measured object aiming measurement. And drive the optical ruler through the workbench, move in the X and Y direction by THE DC-3000 multi-functional data processor for data processing, through the software calculus to complete the measurement work. Image measurement is mainly the use of zoom objective to enlarge the object, and then its projection onto the screen tool.

Image measurement, image by CCD to absorb external object, through the photoelectric conversion, the image data information transmitted to the computer, through the computer for image processing, image processing software on the geometric calculation, finally it is concluded that the object position information, the size of the contour parameters such as object, using special follow-up feedback control system to feedback control of machine tool processing, It has the characteristics of non-contact, real-time and high precision. The general framework of the image measurement system is shown in the figure below:

1-220404044250Z2.png

The image acquisition system includes optical imaging system (lighting source), image sensor, optical lens and image acquisition card. The image quality collected by the system directly affects the accuracy of the subsequent processing process, which is an important prerequisite for high-precision measurement. The quality of the image processing algorithm also directly affects the real-time performance and accuracy of the system.

客服1

客服1